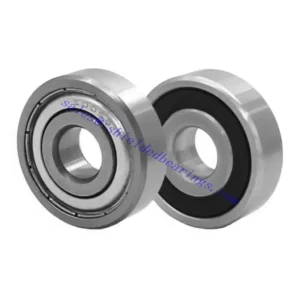

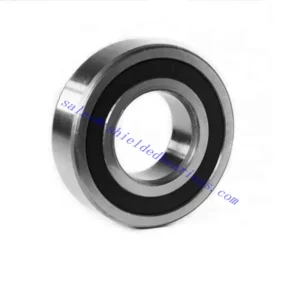

Shielded Bearings

HIGH QUALITY HIGH PRECISE Manufacturer & Supplier

What Is A Shielded Bearings?

A shielded bearing is a type of rolling element bearing that is designed with shields or plates to protect against external contaminants and debris. The shields on the bearing act as a barrier, preventing dirt, dust, and other debris from entering the bearing and causing damage. This protection is particularly important in harsh environments where the bearing is exposed to extreme temperatures, moisture, or chemicals.

Overall, shielded bearings are a reliable and efficient solution for protecting bearings against contaminants and reducing friction and wear. They are a popular choice for many industries due to their versatility, durability, and ability to provide protection in harsh environments.

Shielded Bearings Advantages

Protection against contaminants

One of the main advantages of shielded bearings is the ability to keep contaminants out. The shields on the bearings act as a barrier to prevent dirt, dust and other debris from entering the bearings and causing damage.

Reduced friction and wear

Shielded bearings help retain lubricant and prevent it from escaping. This ensures that the bearings run smoothly and efficiently, reducing the amount of friction and wear on the bearings.

Improved performance

Shielded bearings can improve the performance of the equipment they are used in. By reducing friction and wear, they can help to improve the efficiency and accuracy of machinery, leading to improved productivity and higher quality products.

How an shielded bearings works?

Loading: A shielded bearing consists of an inner ring, an outer ring, rolling elements such as balls or rollers, and a shield or plate.

Protection from Contaminants: The shields on the bearings act as a barrier, preventing dirt, dust and other debris from entering the bearings and causing damage.

Lubricant Retention: Shielded bearings help retain lubricant and prevent it from escaping.

Reduced friction and wear: By retaining lubricant and preventing contamination, shielded bearings reduce the amount of friction and wear on the bearing.

Smooth running: As the rolling elements move between the inner and outer rings, shields on the bearing help hold them in place and prevent them from rubbing against each other.

Shielded Bearings Design

The design of shielded bearings is based on the following principles:

- The shield must be able to prevent contaminants from entering the bearing. The shield is typically made of a metal, such as steel or aluminum, that is resistant to corrosion. The shield is also designed to be open at the ends, which allows the bearing to ventilate. This helps to prevent the bearing from overheating and to keep the lubricant from becoming contaminated.

- The shield must not interfere with the bearing’s operation. The shield must be designed to fit snugly around the bearing, but it must not restrict the bearing’s movement. The shield must also be designed to be as thin as possible, so that it does not add unnecessary weight or friction to the bearing.

- The shield must be durable and long-lasting. The shield must be able to withstand the harsh conditions that the bearing is exposed to. The shield must also be able to withstand the forces that are applied to the bearing during operation.

Shielded Bearings For sale

Application of Shielded Bearings

Shielded bearings are often used in industrial machinery, such as conveyors, pumps, and motors. These machines are often exposed to dirt, dust, and moisture, so shielded bearings help to protect the bearings from these contaminants.

Shielded bearings are also used in marine applications, such as boat propeller bearings and rudder bearings. These bearings are often exposed to saltwater, so shielded bearings help to protect the bearings from corrosion.

Shielded bearings are also used in automotive applications, such as wheel bearings and transmission bearings. These bearings are often exposed to road dirt and debris, so shielded bearings help to protect the bearings from these contaminants.

Shielded bearings are also used in food processing applications, such as conveyors and mixers. These bearings are often exposed to food particles and liquids, so shielded bearings help to protect the bearings from contamination.

We’re Here To Help!

Our commitment to customers:stomers:

◆ Outstanding expertise for optimum performance and reliability

◆ best cost-benefit ratio

◆ Short reaction times and high product availability

Custom Design

As a service to our customers, we offer extensive manufacturing experience and talent to meet the special needs of custom parts. Our in-house engineering team has extensive experience in designing and custom engineering solutions to meet your requirements. If you don’t see what you’re looking for in our standard range, please inquire about custom options.